Abstract

PURPOSE: Non-melanoma Skin cancers occurring in areas with irregular contours like the ear pose challenges in effectively delivering a therapeutic radiation dose using electrons. As electrons deliver dose at a depth, a tissue equivalent material called bolus must be placed on the skin so that therapeutic dose is delivered to the tumor. Commercially available bolus materials lack the ability to conform to a patient’s specific anatomy in areas with irregular contours. Such shortcomings can create air cavities between the tumour and bolus, and ultimately lead to treatment inaccuracy. A custom bolus can be made from wax, but this also has shortcomings. It is labour intensive and challenging to create a wax bolus with uniform specified thickness and minimal air gaps. As an alternative, we have developed a technique of generating soft silicone bolus, which conforms to irregular anatomy, using an optical scanner and rigid material 3D printer.

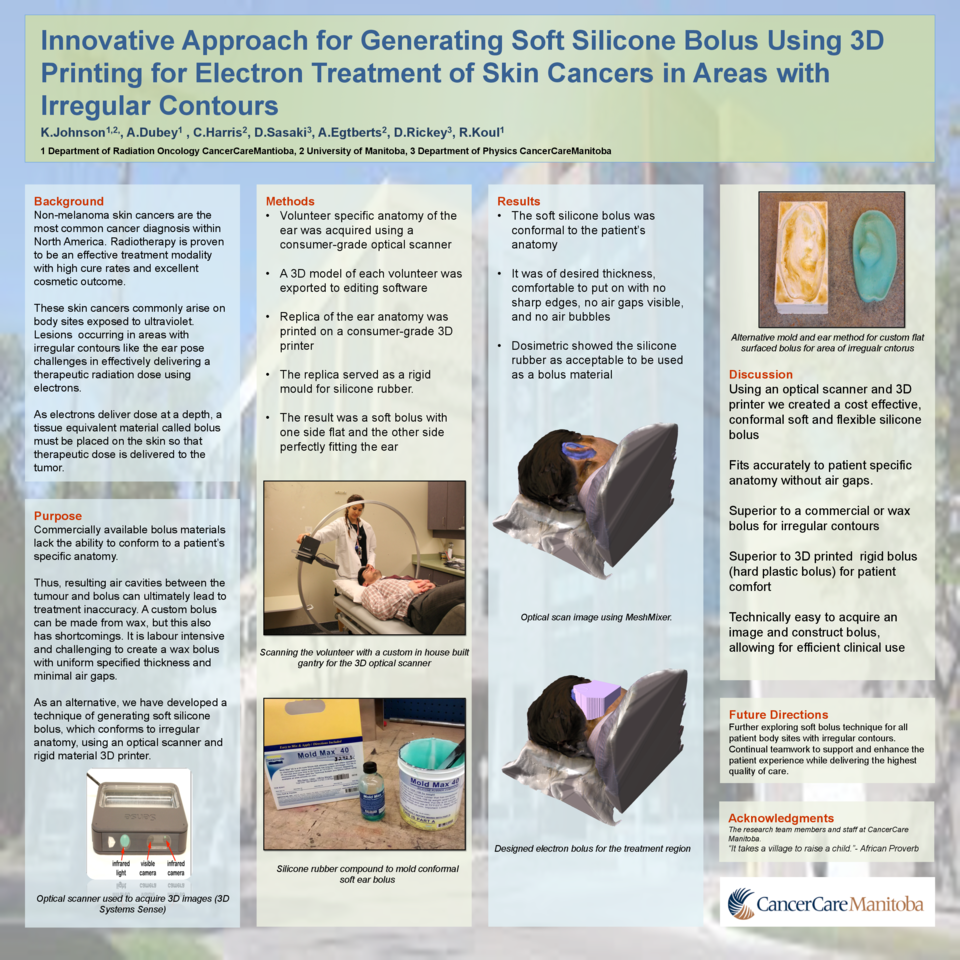

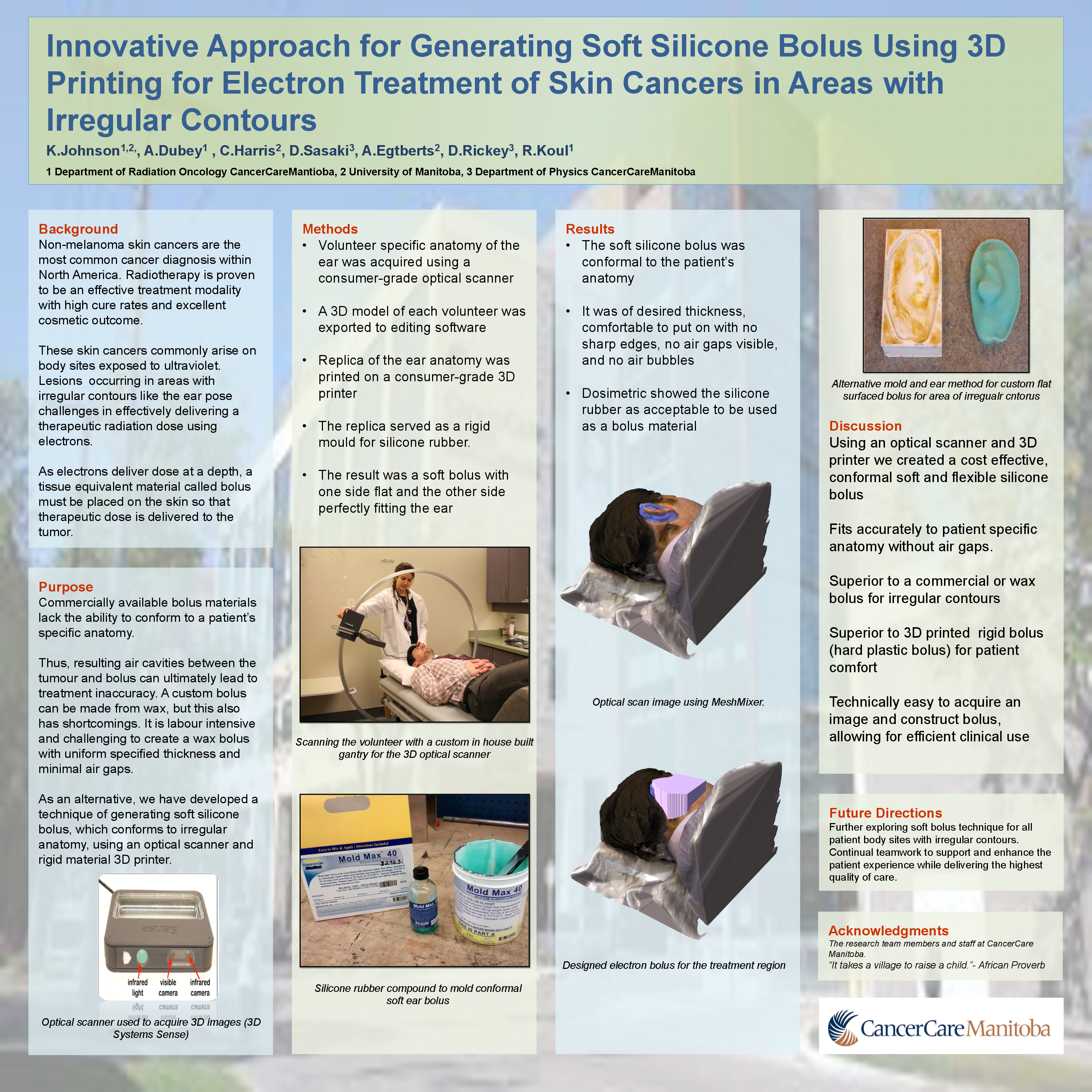

MATERIALS AND METHODS: Volunteer specific anatomy of the ear was acquired using a consumer-grade optical scanner (3D Systems, Sense). A three-dimensional model of each volunteer was exported to a mesh editing software (Autodesk, MeshMixer v2.9) where replica of the ear anatomy was designed. This replica was exported as an STL file to software controlling the printer (Repetier-Host), converted to gcode (Slic3r) and printed on a consumer-grade 3D printer (MakerGear, M2). This replica served as a rigid mould for silicone rubber. The result was a soft bolus with one side flat and the other side perfectly fitting the ear.

RESULTS: The soft silicone bolus created by this technique perfectly fit the anatomy, was of desired thickness, comfortable to put on with no sharp edges. There were no air gaps visible. No air bubbles were found using x-ray imaging. Dosimetric studies were done on the silicone rubber and it was found acceptable to be used as a bolus material.

CONCLUSIONS: Using an optical scanner and 3D printer enables us to create a soft, flexible silicone conformal bolus which is cost effective. Silicone bolus accurately fits with no air gaps and is better for irregular contours than a commercial or wax bolus. It is also better than a hard plastic 3D printed bolus for areas where a rigid bolus is difficult to use or causes patient discomfort. This approach does not require intensive training and enhances the patient experience as they can have an optical scan on the day of clinical appointment and directly come on the day of treatment. It also has potential to save treatment machine time because the setup time is anticipated to be reduced as the complexity of set up is greatly decreased.