Abstract

PURPOSE/OBJECTIVES

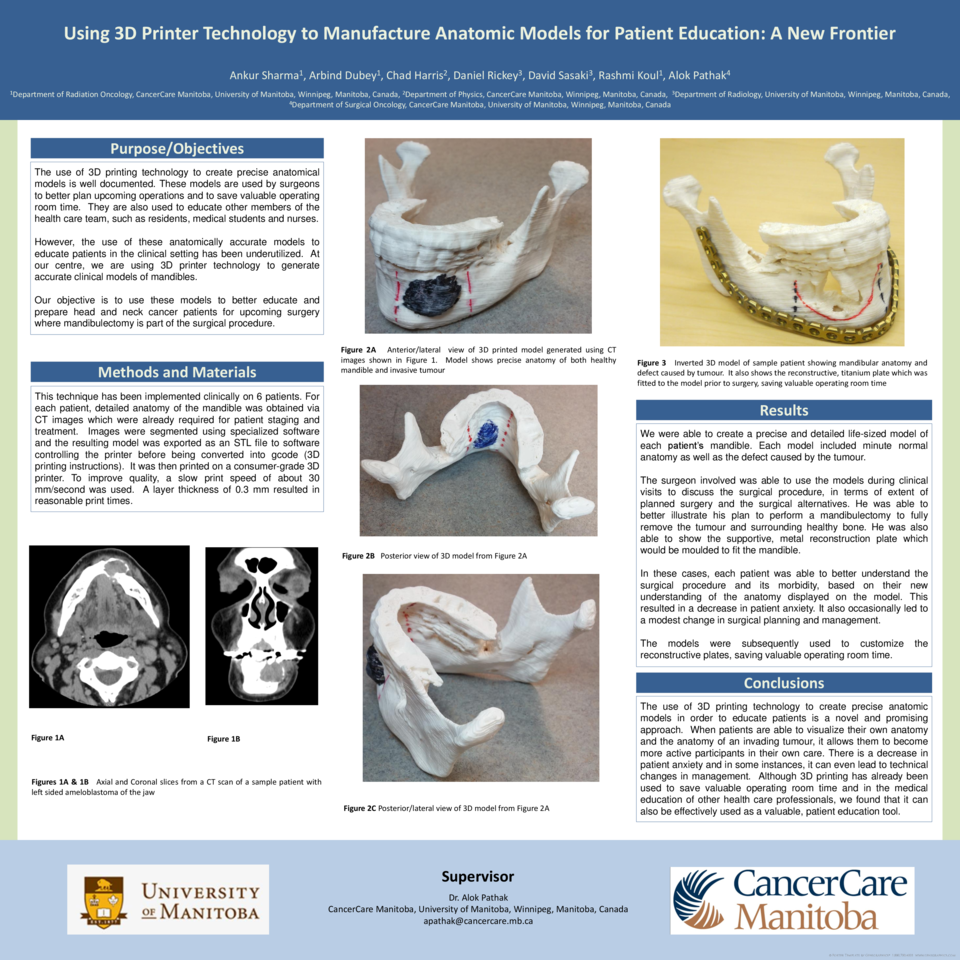

The use of 3D printing technology to create precise anatomical models is well documented. These models are used by surgeons to better plan upcoming operations and to save valuable operating room time. They are also used to educate other members of the health care team, such as residents, medical students and nurses. However, the use of these anatomically accurate models to educate patients in the clinical setting has been underutilized. At our centre, we are using 3D printer technology to generate accurate clinical models of mandibles. Our objective is to use these models to better educate and prepare head and neck cancer patients for upcoming surgery where manibulectomy is part of the surgical procedure. This has been used to educate 3 consecutive patients.

MATERIALS/METHODS

For each patient, detailed anatomy of the mandible was obtained via CT images which were already required for patient staging and treatment. Images were segmented (3D Doctor, Able Software) and the resulting model was exported as an STL file to software controlling the printer (Repetier-Host), converted to gcode (Slic3r) and printed on a consumer-grade 3D printer (MakerGear, M2). To improve quality, a slow print speed of about 30 mm/second was used. A layer thickness of 0.3 mm resulted in reasonable print times.

RESULTS

We were able to create a precise and detailed life-size model of the patient’s mandible for 3 patients. Each model included minute normal anatomy as well as the defect created by the tumour.

The surgeon involved was able to use the models during clinical visits to educate the patients. He was able to better illustrate his plan to perform a mandibulectomy to fully remove the tumour and surrounding healthy bone. He was also able to show the supportive, metal reconstruction plate which would be moulded to fit the mandible. In these cases, each patient was able to give suggestions based on personal preferences and their new understanding of the anatomy displayed on the model. This resulted in a decrease in patient anxiety. It also led to a modest change in surgical planning and management. The models were subsequently used to customize the reconstructive plates.

CONCLUSION

The use of 3D printing technology to create precise anatomic models in order to educate patients is a novel and promising approach. When patients are able to visualize their own anatomy and the anatomy of an invading tumour, it allows them to be more involved in their own care. There is a decrease in anxiety and in some instances, it can even lead to technical changes in management. Although 3D printing has already been used to save valuable operating room time and in the medical education of other health care professionals, we found that it can be effectively used as a valuable, patient education tool.